Halogen-free, Low smoke, Highly Flame Retardant, Heat Shrinkable

- MSVLD

- Halogen free low smoke emission materials, designed ideally for motor train unit, rail transit, aerospace, and shipbuilding industrials

- Standard temperature resistance, rated temperature 125°C

- Highly flame retardant, low smoke emissive; meets international locomotive relevant standards

- ROHS compliant; meets SONY SS-00259

- High reliability, permanent identification

- Heat sensitive, swift recovery

- Computer printable, any characters and logo are easy to design

- Detailed

Halogen-free, Low smoke, Highly Flame Retardant, Heat Shrinkable Wire Identification Sleeves

Description

VLD(DIN) series is the halogen free, low smoke, highly flame retardant cable and wire identification sleeves, which is designed to meet the requirements of EMU for high-speed rails, subways and motor train units. It is made of the polyolefin by means of bombarding and cross-lining of high energy electron beam. Flammability, smoke density, toxicity index, electrical, physical and chemical performances conform to the standards of international motor vehicles. The printed characters are amazingly abrasion resistant, even if the words have encountered detergent or corrosion of military oil before and after shrinking. The soundness of words conforms to the requirements of SAE-AS 81531 and MIL-STD-202F/215J and keeps permanent identification.

Features

● Halogen free low smoke emission materials, designed ideally for motor train unit, rail transit, aerospace, and shipbuilding industrials

● Standard temperature resistance, rated temperature 125°C

● Highly flame retardant, low smoke emissive; meets international locomotive relevant standards

● ROHS compliant; meets SONY SS-00259

● High reliability, permanent identification

● Heat sensitive, swift recovery

● Computer printable, any characters and logo are easy to design

Rated Temperature

● Continuous operating temperature: -55°C~125°C/-67°F~257°F

● Min. shrink temperature: 85°C/185°F

● Full recovery temperature: 115°C~200°C/239°F~392°F, 8~3minutes

● Max. storage and transportation temperature: ≤50°C/122°F

Standards

● Raw material Standards: ASTM D 2671/DIN5510-2

● Color code soundness: SAE-AS 81531 and MIL-STD-202F/215J

● British and French Smoke Poison Standards: BS 6853/NF F 16-101

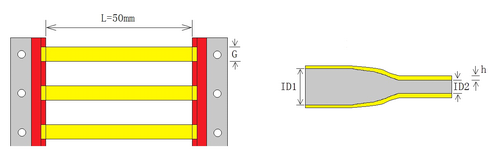

Structure

Technical Performance

|

Performance |

Indicators |

Test Method |

||

|

Typical properties |

Unit |

States |

||

|

Tensile Strength |

Mpa |

Unaged |

≥10.3 |

ASTM G 154,MIL-DTL-23053E ISO 37,500mm/min 175°C,168h,ISO 188 |

|

Heat aged/ After fluids/UV aged |

≥6.9 |

|||

|

Elongation at break |

% |

Unaged |

≥200 |

|

|

Heat aged/ After fluid |

≥100 |

|||

|

Secant Modulus |

Mpa |

Unaged |

<173 |

ASTM D 882 |

|

Voltage Withstand |

V |

Unaged / After aged |

2500V, No breakdown in 60 sec. |

IEC 243,ASTM G 154 175°C,168h,ISO 188 |

|

Dielectric Strength |

MV/m |

Before aged |

≥19.7 |

|

|

Heat aged/ After fluid/ UV aged |

≥15.8 |

|||

|

Volume Resistivity |

Ω.cm |

Unaged |

≥1014 |

IEC 93 |

|

Dielectric constant |

- |

Unaged |

- |

ASTM 150 |

|

Water Absorption |

- |

Unaged |

≤1.0 |

ASTM 570,23°C,24h |

|

Bare Copper Corrosion |

- |

Unaged |

No corrosion |

23°C,Rh 95±5%,24h 175°C,16h |

|

Heat Shock |

- |

Unaged |

No cracks, flowing, dripping |

Wind to the specified mandrel, 225°C,4h |

|

Cold Flexibility |

- |

Unaged |

No cracks |

Wind to the specified mandrel, -30°C,1h |

|

Flammability |

- |

Unaged |

DIN 5510, S3 |

DIN 5510-2 |

|

Longitudinal Change |

% |

Unaged |

2X: -10~+1 |

200°C,Constant 3min |

|

3X: -15~+5 |

||||

|

Smoke Density |

- |

Unaged |

≤0.017 |

DIN 5510-2 |

|

Toxcity Index |

- |

Unaged |

≤1 |

BS 6853:1999 |

Dimensions(2:1)

|

Order Description |

Expanded As Supplied (mm) |

Recovered After Heating (mm) |

|||

|

Inner Diameter ID1 |

Flatten width G |

Dual Wall Thickness H |

Inner DiameterID2 |

Single Wall Thickness h |

|

|

MSVLD-2X-1.6/ |

2.00±0.20 |

3.7±0.3 |

0.48±0.10 |

≤0.79 |

0.45±0.06 |

|

MSVLD-2X-2.4/ |

2.79±0.20 |

5.0±0.3 |

0.48±0.10 |

≤1.18 |

0.49±0.06 |

|

MSVLD-2X-3.2/ |

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.59 |

0.51±0.06 |

|

MSVLD-2X-4.8/ |

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤2.36 |

0.54±0.06 |

|

MSVLD-2X-6.4/ |

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤3.18 |

0.56±0.06 |

|

MSVLD-2X-9.5/ |

10.2±0.32 |

16.7±0.5 |

0.51±0.11 |

≤4.75 |

0.59±0.06 |

|

MSVLD-2X-12.7/ |

13.5±0.36 |

21.8±0.6 |

0.52±0.11 |

≤6.35 |

0.60±0.07 |

|

MSVLD-2X-19/ |

20.1±0.40 |

32.2±0.6 |

0.53±0.11 |

≤9.53 |

0.62±0.07 |

|

MSVLD-2X-25/ |

26.7±0.45 |

42.5±0.7 |

0.55±0.12 |

≤12.7 |

0.63±0.07 |

|

MSVLD-2X-38/ |

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤19.1 |

0.64±0.07 |

|

MSVLD-2X-51/ |

53.0±0.56 |

83.9±0.9 |

0.58±0.13 |

≤25.4 |

0.64±0.08 |

|

MSVLD-2X-76/ |

79.4±0.56 |

125.3±1.0 |

0.59±0.13 |

≤38.1 |

0.64±0.09 |

Dimensions(3:1)

|

Order Description |

Expanded As Supplied(mm) |

Recovered After Heating(mm) |

|||

|

Internal Diameter ID1 |

Flatten Width G |

Dual Wall Thickness H |

Inner Diameter ID2 |

Single Wall Thickness h |

|

|

MSVLD-3X-1.6/ |

2.00±0.20 |

3.7±0.3 |

0.47±0.10 |

≤0.53 |

0.52±0.06 |

|

MSVLD-3X-2.4/ |

2.79±0.20 |

5.0±0.3 |

0.47±0.10 |

≤0.79 |

0.57±0.06 |

|

MSVLD-3X-3.2/ |

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.06 |

0.61±0.06 |

|

MSVLD-3X-4.8/ |

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤1.59 |

0.67±0.06 |

|

MSVLD-3X-6.4/ |

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤2.36 |

0.71±0.06 |

|

MSVLD-3X-9.5/ |

10.2±0.32 |

16.7±0.5 |

0.52±0.11 |

≤3.18 |

0.77±0.06 |

|

MSVLD-3X-12.7/ |

13.5±0.36 |

21.8±0.6 |

0.53±0.11 |

≤4.75 |

0.80±0.07 |

|

MSVLD-3X-19/ |

20.1±0.40 |

32.2±0.6 |

0.55±0.11 |

≤6.35 |

0.84±0.07 |

|

MSVLD-3X-25/ |

26.7±0.45 |

42.5±0.7 |

0.56±0.12 |

≤8.47 |

0.86±0.07 |

|

MSVLD-3X-38/ |

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤12.9 |

0.89±0.07 |

|

MSVLD-3X-51/ |

53.0±0.56 |

83.9±0.9 |

0.57±0.13 |

≤17.2 |

0.90±0.08 |

|

MSVLD-3X-76/ |

79.4±0.56 |

125.3±1.0 |

0.59±0.13 |

≤25.8 |

0.92±0.09 |

Standard Packaging Data

|

No. |

Sizes |

Packaging(Pcs/Reel) |

|

|

Box 210 |

Box 146 |

||

|

1 |

Φ1.6 |

2500 |

250 |

|

2 |

Φ2.4 |

2500 |

250 |

|

3 |

Φ3.2 |

2000 |

250 |

|

4 |

Φ4.8 |

2000 |

250 |

|

5 |

Φ6.4 |

1500 |

250 |

|

6 |

Φ9.5 |

1000 |

250 |

|

7 |

Φ12.7 |

500 |

250 |

|

8 |

Φ19 |

500 |

250 |

|

9 |

Φ25 |

500 |

250 |

|

10 |

Φ38 |

250 |

250 |

|

11 |

Φ51 |

250 |

250 |

|

12 |

Φ76 |

250 |

250 |