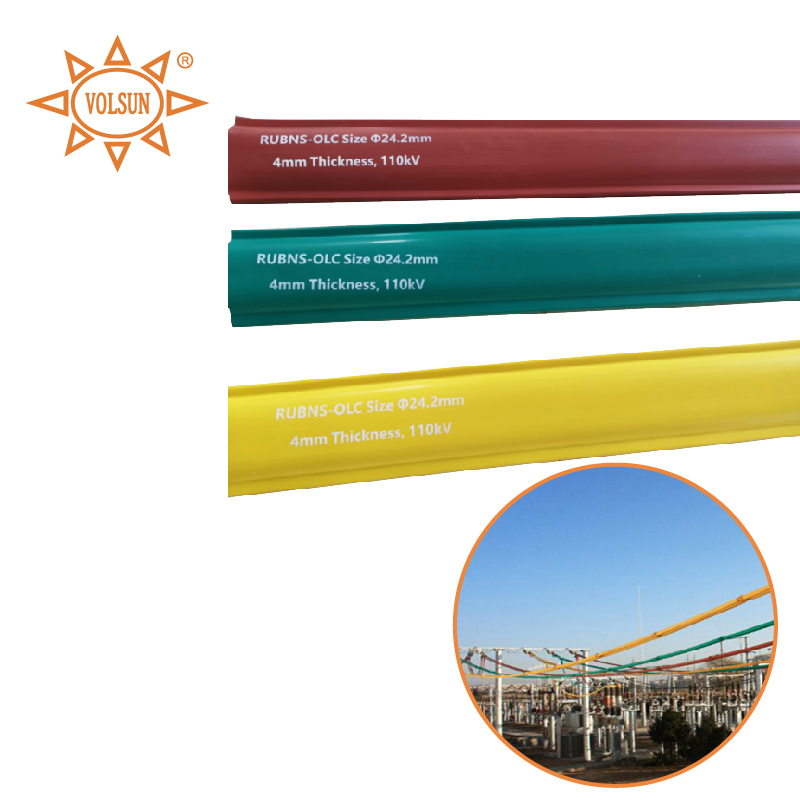

Silicone Rubber Material Overhead Power Line Conductor Cover

- Detailed

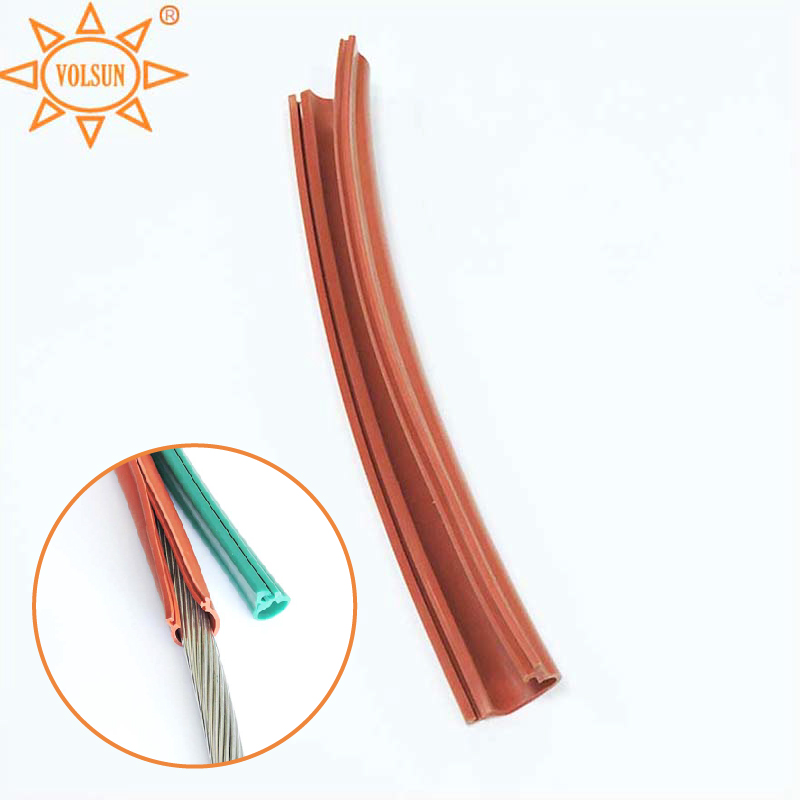

RUBNS-OLC is made of high-quality silicone rubber material. It has excellent electrical and tracking resistance, excellent weather resistance, high mechanical properties, hydrophobicity and hydrophobic migration, and excellent high and low temperature resistance. It can be used continuously under the temperature of -50℃~+150℃. It is convenient and simple to install, saves labor and time, and is used for insulation protection of cables and wires to increase the safe distance between objects and cables.

Features

- Soft and fold-resistant

- Long service life, anti-aging, and corrosion resistance

- Simple installation, no fire, power outage construction time is short

Item

Typical Data

Test Method

Electrical Strength Test

≥20kV/mm

GB/T 1408.1-2006

Volume Resistivity

≥1×1014Ω·cm

GB/T 1410-2006

Dielectric Constant

2~3

GB/T 1409-2006

Shore Hardness

70±5A

GB/T 531

Mechanical Property

Before heat ageing

Tensile Strength

≥4.0MPa

GB/T 528-2009

Elongation at break

≥200%

GB/T 528-2009

After Heat aging (180℃,

7d)

Tensile Strength Change

±30%

GB/T 528-2009

Elongation Change

±30%

GB/T 528-2009

Low Temperature Elongation(-15℃,

2h)

≥20%

GB/T 2951.4-1997

Low Temperature Flexibility(-50℃,

4h)

No cracks

UL224-2004

High Temperature Crack Resistance(155℃,

2h)

No cracks

GB/T2951.6-1997

Recommended Size for LG Type Aluminum Stranded Wires

Nominal

cross-sectional area (mm²)

Recommended Inner Diameter of Conductor

Cover (mm)

50~70

Ф12

95~120

Ф17

150~185

Ф20

210~300

Ф24.2

400

Ф30

500

Ф32

630

Ф35

800

Ф39.8

Recommended size for LGJ Type Steel Core Aluminum Stranded Wires & LGJF Type Anti-corrosion Steel Core Aluminum Stranded Wires

Nominal cross-sectional area (mm²) 对应绝缘护套管规格(mm)

Recommended Inner Diameter of Conductor

Cover (mm)

35

50

Ф12

Ф15.6

70~95

120~150

185~240

Ф17

Ф20

Ф24.2

400~500

800~800

Ф32

Ф39.8

Note: Special sizes and packaging can be customized upon request.

Correspondence table between voltage and wall thickness

|

Voltage(KV) |

≤10kV |

≤35kV |

≤110kV |

≤220kV |

|

Wall thickness |

2.0±0.3mm |

3.0±0.4mm |

4.0±0.5mm |

6.0±1.0mm |