Halogen Free Heat Shrinkable Wire Identification Sleeves

- MS-VLU

- Halogen free, ideally used for electronic or electrical circuits, communications, architectural industries

- emp. Resistance: 125°C

- Highly flame retardant, VW-1

- ROHS compliant and meet SONY SS-00259

- High reliability, permanent identification

- Heat sensitive, shrinking quickly

- Computerized lettering or fonts at your disposal.

- Standard Color: yellow, white

- Detailed

Halogen Free Environmentally Friendly Heat Shrinkable Wire Identification Sleeves

Description

MSVLU series is halogen free, environmentally friendly, heat shrinkable identification sleeves. It is made of cross-linked environmentally friendly polyolefin bombarded by high power electron beam with electronic accelerators to meet high end markets where highly reliable, economical and environmentally friendly cable& wire identification is required. It accords to the requirements of UL224, CAN/CSA C22.2. Shrink ratios, both 2:1 and 3:1 are available. See the below tables.

Features

● Halogen free, ideally used for electronic or electrical circuits, communications, architectural industries

● emp. Resistance: 125°C

● Highly flame retardant, VW-1

● ROHS compliant and meet SONY SS-00259

● High reliability, permanent identification

● Heat sensitive, shrinking quickly

● Computerized lettering or fonts at your disposal.

● Standard Color: yellow, white

Rated Temperature

● Continuous operating temperature: -55°C~125°C/-67°F~257°F

● Min. shrink temperature: 85°C/185°F

● Full recovery temperature: 115°C~200°C/239°F~392°F, 8~3minutes

● Max. storage and transportation temperature: ≤50°C/122°F

Standards

● Material Standard: UL224, CAN/CSA C22.2

● Color Code Soundness: SAE-AS 81531and MIL-STD-202F/215J

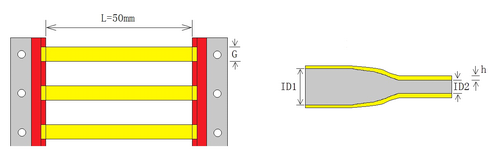

Structure

Technical Performance

|

Performance |

Indicators |

Test Method |

||

|

Typical properties |

Unit |

States |

||

|

Tensile Strength |

Mpa |

Unaged |

≥10.3 |

ASTM G 154,MIL-DTL-23053E ISO 37,500mm/min 175°C,168h,ISO 188 |

|

Heat aged/ After fluids/UV aged |

≥6.9 |

|||

|

Elongation at break |

% |

Unaged |

≥200 |

|

|

Heat aged/ After fluid |

≥100 |

|||

|

Secant Modulus |

Mpa |

Unaged |

<173 |

ASTM D 882 |

|

Voltage Withstand |

V |

Unaged / After aged |

2500V, No breakdown in 60 sec. |

IEC 243,ASTM G 154 175°C,168h,ISO 188 |

|

Dielectric Strength |

MV/m |

Before aged |

≥19.7 |

|

|

Heat aged/ After fluid/ UV aged |

≥15.8 |

|||

|

Volume Resistivity |

Ω.cm |

Unaged |

≥1014 |

IEC 93 |

|

Dielectric constant |

- |

Unaged |

- |

ASTM 150 |

|

Water Absorption |

- |

Unaged |

≤1.0 |

ASTM 570,23°C,24h |

|

Bare Copper Corrosion |

- |

Unaged |

No corrosion |

23°C,Rh 95±5%,24h 175°C,16h |

|

Heat Shock |

- |

Unaged |

No cracks, flowing, dripping |

Wind to the specified mandrel,225°C,4h |

|

Cold Flexibility |

- |

Unaged |

No cracks |

Wind to the specified mandrel, -30°C, 1h |

|

Flammability |

- |

Unaged |

VW-1 |

IEC 60332-1-3 Ed.1.0 b:2004 |

|

Longitudinal Change |

% |

Unaged |

2X: -10~+1 |

200°C,Constant 3min |

|

3X: -15~+5 |

||||

|

Smoke Density |

- |

Unaged |

- |

DIN 5510-2 |

|

Toxcity Index |

- |

Unaged |

- |

BS 6853:1999 |

Dimensions(2:1)

|

Order Description |

Expanded As Supplied (mm) |

Recovered After Heating (mm) |

|||

|

Inner Diameter ID1 |

Flatten width G |

Dual Wall Thickness H |

Inner DiameterID2 |

Single Wall Thickness h |

|

|

MSVLU-2X-1.6/ |

2.00±0.20 |

3.7±0.3 |

0.48±0.10 |

≤0.79 |

0.45±0.06 |

|

MSVLU-2X-2.4/ |

2.79±0.20 |

5.0±0.3 |

0.48±0.10 |

≤1.18 |

0.49±0.06 |

|

MSVLU-2X-3.2/ |

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.59 |

0.51±0.06 |

|

MSVLU-2X-4.8/ |

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤2.36 |

0.54±0.06 |

|

MSVLU-2X-6.4/ |

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤3.18 |

0.56±0.06 |

|

MSVLU-2X-9.5/ |

10.2±0.32 |

16.7±0.5 |

0.51±0.11 |

≤4.75 |

0.59±0.06 |

|

MSVLU-2X-12.7/ |

13.5±0.36 |

21.8±0.6 |

0.52±0.11 |

≤6.35 |

0.60±0.07 |

|

MSVLU-2X-19/ |

20.1±0.40 |

32.2±0.6 |

0.53±0.11 |

≤9.53 |

0.62±0.07 |

|

MSVLU-2X-25/ |

26.7±0.45 |

42.5±0.7 |

0.55±0.12 |

≤12.7 |

0.63±0.07 |

|

MSVLU-2X-38/ |

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤19.1 |

0.64±0.07 |

|

MSVLU-2X-51/ |

53.0±0.56 |

83.9±0.9 |

0.58±0.13 |

≤25.4 |

0.64±0.08 |

|

MSVLU-2X-76/ |

79.4±0.56 |

125.3±1.0 |

0.59±0.13 |

≤38.1 |

0.64±0.09 |

Dimensions(3:1)

|

Order Description |

Expanded As Supplied (mm) |

Recovered After Heating (mm) |

|||

|

Internal Diameter ID1 |

Flatten Width G |

Dual Wall Thickness H |

Inner Diameter ID2 |

Single Wall Thickness h |

|

|

MSVLU-3X-1.6/ |

2.00±0.20 |

3.7±0.3 |

0.47±0.10 |

≤0.53 |

0.52±0.06 |

|

MSVLU-3X-2.4/ |

2.79±0.20 |

5.0±0.3 |

0.47±0.10 |

≤0.79 |

0.57±0.06 |

|

MSVLU-3X-3.2/ |

3.64±0.23 |

6.3±0.4 |

0.48±0.10 |

≤1.06 |

0.61±0.06 |

|

MSVLU-3X-4.8/ |

5.26±0.25 |

8.9±0.4 |

0.49±0.10 |

≤1.59 |

0.67±0.06 |

|

MSVLU-3X-6.4/ |

6.92±0.28 |

11.5±0.4 |

0.50±0.10 |

≤2.36 |

0.71±0.06 |

|

MSVLU-3X-9.5/ |

10.2±0.32 |

16.7±0.5 |

0.52±0.11 |

≤3.18 |

0.77±0.06 |

|

MSVLU-3X-12.7/ |

13.5±0.36 |

21.8±0.6 |

0.53±0.11 |

≤4.75 |

0.80±0.07 |

|

MSVLU-3X-19/ |

20.1±0.40 |

32.2±0.6 |

0.55±0.11 |

≤6.35 |

0.84±0.07 |

|

MSVLU-3X-25/ |

26.7±0.45 |

42.5±0.7 |

0.56±0.12 |

≤8.47 |

0.86±0.07 |

|

MSVLU-3X-38/ |

39.8±0.51 |

63.2±0.8 |

0.57±0.12 |

≤12.9 |

0.89±0.07 |

|

MSVLU-3X-51/ |

53.0±0.56 |

83.9±0.9 |

0.57±0.13 |

≤17.2 |

0.90±0.08 |

|

MSVLU-3X-76/ |

79.4±0.56 |

125.3±1.0 |

0.59±0.13 |

≤25.8 |

0.92±0.09 |

Standard Packaging Data

|

No. |

Sizes |

Packaging (Pcs/Reel) |

|

|

Box 210 |

Box 146 |

||

|

1 |

Φ1.6 |

2500 |

250 |

|

2 |

Φ2.4 |

2500 |

250 |

|

3 |

Φ3.2 |

2000 |

250 |

|

4 |

Φ4.8 |

2000 |

250 |

|

5 |

Φ6.4 |

1500 |

250 |

|

6 |

Φ9.5 |

1000 |

250 |

|

7 |

Φ12.7 |

500 |

250 |

|

8 |

Φ19 |

500 |

250 |

|

9 |

Φ25 |

500 |

250 |

|

10 |

Φ38 |

250 |

250 |

|

11 |

Φ51 |

250 |

250 |

|

12 |

Φ76 |

250 |

250 |