Ultro-sonic Welding Technology of Cold Shrink Tubing

Time: 2015-11-19 16:07:58 Copyfrom: volsun

Volsun Electronics keep using ultro-sonic welding tech for the spiralcore inside the Cold Shrink Tubing. Compare with Hot Air Welding Tech, Ultro-sonic is much more powerful for supporting, and more easier to remove.

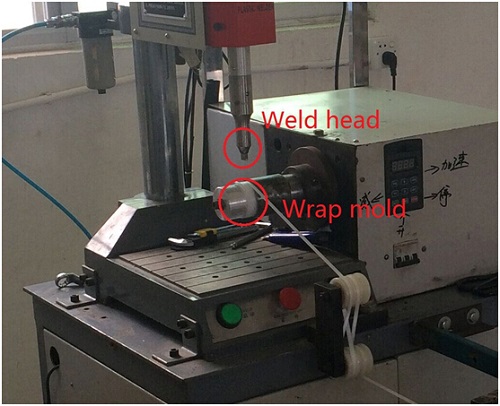

Below is the photo of our ultra-sonic welding machine.

We use the wrap mold with gears to wrap the plastic core.

1. The gears pull the plastic core to move forward.

2. Once be wrapped as a roll, the weld head will weld it.

3. The mold will move forward a little at the same time to ensure the next roll can be wrapped with enough space.

4. When the spiral core meet the length we want, cut it directly.

5. And move it from the mold carefully.

Before March 2015, the gears project from the surface of the wall, and a little sharp.Sharp gears can pull the plastic core more easily with less power.

The problem is when spiral core moved from the mold, the sharp gears will hurt the core if careless.

So we redesign the mold with blunt gears, easy pull and avoid the damage at the same time.When we move the spiral core from the mold, there is no hurt inside.

Volsun®Cold Shrink Tubing, high temperature resistant, acid and alkali resistant, solvent resistant, also resistance to external mechanical damage.

Quality is our culture.Volsun Electronics, your ideal partner for industrial insulation, sealing and protection.

Any comments or questions, please contact us.