Heat shrink marker sleeve for electronic industry

Time: 2015-07-22 10:47:20 Copyfrom: volsun

In the electronic assembly, in order to facilitate production, commissioning, repair, testing, often need to mark the end of the assembly cable, called making cable signs.

There are many methods of making cable signs.In the past, Volsun has two methods to produce cable signs:

Aluminum plate: Using 0.5mm thick aluminum sheet cut into t-shaped ,then engraving characters on the blank via hand-lettering and fonts. lettering in the blank characters. This method involved time-consuming work late, not suitable for mass production. And easy to loose, cannot be used for airborne and air-borne electronic equipment.

Plastic casing label: Writing character by hand on the plastic casing. Actually, the character is neither beautiful nor clear, labels only under normal temperature and short life.

At present, these two methods can not meet modern electronic product’s requirement.

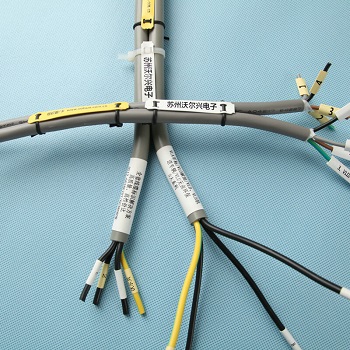

Volsun has developed a new-type heat shrink marker sleeve, which takes a computer-aided design technology and appropriate signage of assembly process.

This heat shrink marker sleeve is made of cross-linked polyolefin bombarded by high power electron beam with electronic accelerators to meet high end markets where highly reliable. We use thermal transfer printer to print character on the sleeves. Then heating shrink the marker sleeves on the cable terminal.

In this way, heat shrink marker sleeve is more flexible and corrosion resistant than Plastic casing label and Aluminum plate.

Any interests please contact our Overseas Sales Manager.