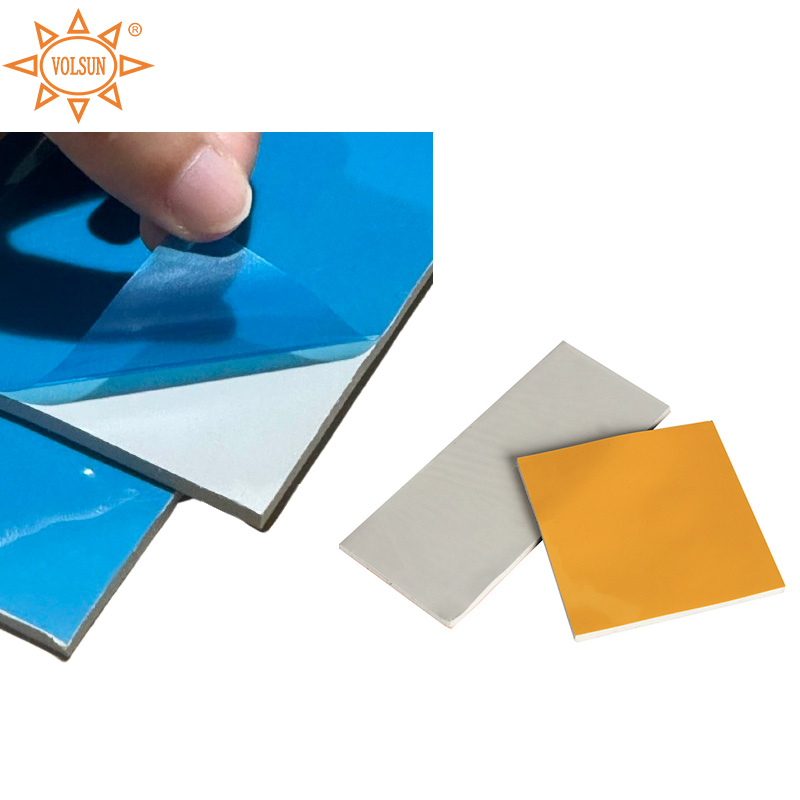

Volsun Silicone Thermal Pads for New Energy Vehicle Electronic Systems

Time: 2025-12-13 16:03:24 Copyfrom: SuZhou Volsun Electronics Technology Co.,Ltd.

In new energy vehicles, thermal management is directly related to safety, performance, and lifespan. Battery overheating can lead to thermal runaway; high temperatures in the electric drive system will reduce energy efficiency and accelerate aging; and if intelligent driving chips cannot dissipate heat in time, it will even cause system frequency reduction or failure. Traditional heat dissipation methods can no longer meet the stringent requirements of high-efficiency, uniform, and reliable heat dissipation for next-generation electronic devices.

Volsun understands the extreme demands of automotive electronics on material reliability and stability. Our silicone thermal interface material series is specifically developed to meet automotive-grade challenges and is widely used in the following core scenarios:

- Battery Management System (BMS): As the "brain" of the battery pack, the stability of the BMS control chip is crucial. Volsun silicone thermal pad materials fit tightly between the chip and the heat sink, ensuring rapid heat dissipation and building the first line of defense for battery safety monitoring.

- Electric Drive and Power Systems: IGBT and MOSFET power modules in motor controllers, OBC on-board chargers, and DC-DC converters are major heat sources. Our high thermal conductivity silicone pads (up to 10W/m·K) effectively reduce module junction temperature, improve energy conversion efficiency and power density, and ensure continuous power output of the vehicle.

- Vehicle Lighting and Sensors: In LED headlights and sensor modules such as lidar and cameras, our ultra-thin and flexible pads solve the heat dissipation problem in confined spaces, significantly delaying device light decay and improving the reliability of the sensing system.

Volsun thermal silicone pads are more than just thermal conductivity; they are a commitment to reliability. Our products are backed by a rigorous system of verification:

- Automotive-grade reliability: The entire silicone thermal pad series meets requirements for high and low temperature resistance (-40℃~200℃+), aging resistance, and vibration resistance, and has passed multiple industry and automotive manufacturer standard tests.

- Electrical insulation protection: Excellent insulation properties ensure high-voltage safety in complex circuit environments.

- Stress buffering protection: Soft materials absorb vibration and assembly stress, protecting delicate chips and solder joints.

- Customized design: We can provide comprehensive technical support from material selection, thickness cutting to shape die-cutting according to your specific thermal design, space, and process requirements.

In the race towards the future of new energy vehicles, efficient thermal management is a crucial factor in determining range and performance. Volsun is committed to becoming your most reliable thermal management partner with its professional materials science expertise, jointly driving a new era of safer, more efficient, and smarter green transportation.

KEYWORD:silicone thermal pads

RELATED_ARTICLES:

How to Select the Right EPDM Cold-Shrink Tube Specifications?

The Application of Cold Shrink Tubes In Electric Power Industry

The difference between EPDM rubber and silicone rubber

Features and application of EPDM cold shrink tube

Application case and technical performance of EPDM cold shrink tube

Large size EPDM cold shrink tube for cable jointing protection

Volsun Restart Normal Work on 20th,2,2021

"Manufacturing Excellence & Innovation Awards" by #madeinchina in 2021

Introduction detail of EPDM cold shrink tube and application

Telecommunication cold shrink tube—EPDM rubber cold shrink tube

Volsun Tapered EPDM Cold Shrink Tube

Volsun EPDM cold shrink tube for power industry and other industrial applications