1.5KV and 2.5KV fiberglass sleeve for new energy automobile industry

Time: 2021-11-25 09:25:15 Copyfrom: SuZhou Volsun Electronics Technology Co.,Ltd.

Description

Silicone resin fiberglass sleeve, by alkali - free glass fiber woven into a tube after coated with silicone resin, and then by high temperature treatment. It has good dielectric property, good softness and temperature resistance. Widely used in motors, household appliances, electrical equipment, electronic devices and cluster wire hardness insulation.

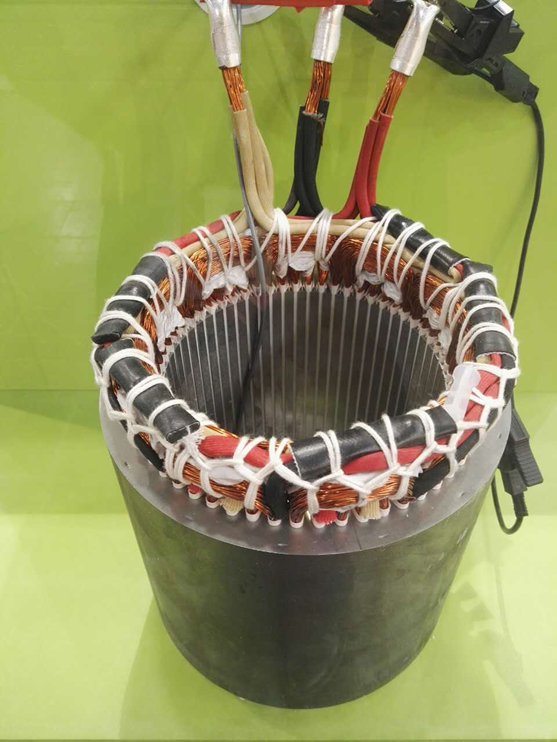

Application picture of fiberglass sleeve for elctronic motor

Features

Operating temperature:-40°C~200 °C

RoHS compliant

Standard color: White, other colors on quest

Technical Performance

|

Type |

Breakdown voltage(V) |

Volume resistivity |

Temperature resistance |

||

|

|

|

||||

|

Average |

Volume resistivity(Ω cm) |

(Ω.cm) |

|||

|

1.5KV |

1500 |

1000 |

1011 |

|

-40℃~200℃ |

|

2.5KV |

2500 |

1800 |

|||

Dimension

|

|

ID(mm) |

|

Wall Thickness(mm) w(mm) |

Packaging (Roll/M) |

|

|

Size |

Tolerance |

1.5KV |

|

2.5KV |

|

|

Φ0.5 |

0~+0.20 |

0.30±0.1 |

|

0.35±0.1 |

200 |

|

Φ0.8 |

0~+0.20 |

0.30±0.1 |

|

0.35±0.1 |

200 |

|

Φ1.0 |

0~+0.20 |

0.30±0.1 |

|

0.35±0.1 |

200 |

|

Φ1.5 |

0~+0.25 |

0.35±0.1 |

|

0.40±0.1 |

200 |

|

Φ2.0 |

0~+0.25 |

0.35±0.1 |

|

0.40±0.1 |

100 |

|

Φ2.5 |

0~+0.25 |

0.35±0.1 |

|

0.40±0.1 |

100 |

|

Φ3.0 |

0~+0.25 |

0.35±0.1 |

|

0.40±0.1 |

100 |

|

Φ3.5 |

0~+0.35 |

0.40±0.1 |

|

0.45±0.1 |

100 |

|

Φ4.0 |

0~+0.35 |

0.40±0.1 |

|

0.45±0.1 |

100 |

|

Φ4.5 |

0~+0.35 |

0.40±0.1 |

|

0.45±0.1 |

100 |

|

Φ5.0 |

0~+0.35 |

0.40±0.1 |

|

0.45±0.1 |

100 |

|

Φ5.5 |

0~+0.40 |

0.45±0.1 |

|

0.50±0.1 |

100 |

|

Φ6.0 |

0~+0.40 |

0.45±0.1 |

|

0.50±0.1 |

100 |

|

Φ7.0 |

0~+0.50 |

0.45±0.1 |

|

0.50±0.1 |

100 |

|

Φ8.0 |

0~+0.50 |

0.45±0.1 |

|

0.50±0.1 |

50 |

|

Φ9.0 |

0~+0.50 |

0.45±0.1 |

|

0.50±0.1 |

50 |

|

Φ10.0 |

0~+0.70 |

0.50±0.15 |

|

0.55±0.15 |

50 |

|

Φ11.0 |

0~+0.70 |

0.50±0.15 |

|

0.55±0.15 |

50 |

|

Φ12.0 |

0~+0.70 |

0.50±0.15 |

|

0.55±0.15 |

50 |

|

Φ13.0 |

0~+0.80 |

0.55±0.15 |

|

0.60±0.15 |

50 |

|

Φ14.0 |

0~+0.80 |

0.55±0.15 |

|

0.60±0.15 |

50 |

|

Φ15.0 |

0~+0.80 |

0.55±0.15 |

|

0.60±0.15 |

50 |

|

Φ16.0 |

0~+0.80 |

0.55±0.15 |

|

0.60±0.15 |

50 |

|

Φ17.0 |

0~+0.80 |

0.60±0.20 |

|

0.60±0.20 |

30 |

|

Φ18.0 |

0~+0.80 |

0.60±0.20 |

|

0.65±0.20 |

30 |

|

Φ19.0 |

0~+0.80 |

0.60±0.20 |

|

0.65±0.20 |

30 |

|

Φ20.0 |

0~+0.80 |

0.60±0.20 |

|

0.65±0.20 |

30 |

|

Φ22.0 |

0~+0.80 |

0.65±0.20 |

|

0.75±0.20 |

30 |

|

Φ25.0 |

0~+0.80 |

0.75±0.20 |

|

0.85±0.20 |

30 |

|

Φ30.0 |

0~+0.80 |

0.85±0.25 |

|

0.95±0.25 |

30 |

Note: Non-standard dimensions and packages also available on your request

KEYWORD:fiberglass sleeve,silicone resin fiberglass sleeve

RELATED_ARTICLES:

How to Select the Right EPDM Cold-Shrink Tube Specifications?

The Application of Cold Shrink Tubes In Electric Power Industry

The difference between EPDM rubber and silicone rubber

Features and application of EPDM cold shrink tube

Application case and technical performance of EPDM cold shrink tube

Large size EPDM cold shrink tube for cable jointing protection

Volsun Restart Normal Work on 20th,2,2021

"Manufacturing Excellence & Innovation Awards" by #madeinchina in 2021

Introduction detail of EPDM cold shrink tube and application

Telecommunication cold shrink tube—EPDM rubber cold shrink tube

Volsun Tapered EPDM Cold Shrink Tube

Volsun EPDM cold shrink tube for power industry and other industrial applications